It’s all bigger in TEXAS!

by steamtug on Oct.19, 2015, under Steamships

I was in awe of the sheer size of South Steyne’s engines when I got to be her engineer while she was in Victoria, many years ago. The largest of Sydney’s Manly ferries and the only one to remain steam powered, had a 4 cylinder, triple expansion engine (LP divided into 2 cylinders) balanced on the “Yarrow, Schlick and Tweedy” system and producing a massive 2,000 horsepower. But a recent trip to Texas USA put things into perspective as I crawled all over the main engines of the USS TEXAS, a world war 1 veteran and now museum ship. USS Texas BB-35 had her keel laid April 1911 in Virginia USA with completion coming in March 1914. She is the last of the world’s “dreadnought” style, big gun battleships and was the most powerful weapon in the world boasting 5 twin turrets equipped with 14” guns which could reach out 14 miles. She is the only surviving US naval ship to have served in both world wars. Her last official duty was to make three “magic carpet” voyages from Pearl Harbor to California, bringing nearly 5000 troops home from the Pacific. After completion of her World War II repatriation duties, and de-commissioning in April 1948, she was scheduled to be used as a bombing target, but Texas citizens launched a successful campaign to have her saved. The U.S. Navy towed her to South East Texas to become the nation’s first permanent memorial battleship when she took up residence at the site of the famous San Jacinto battleground and memorial where she has rested since April 1948.

I was in awe of the sheer size of South Steyne’s engines when I got to be her engineer while she was in Victoria, many years ago. The largest of Sydney’s Manly ferries and the only one to remain steam powered, had a 4 cylinder, triple expansion engine (LP divided into 2 cylinders) balanced on the “Yarrow, Schlick and Tweedy” system and producing a massive 2,000 horsepower. But a recent trip to Texas USA put things into perspective as I crawled all over the main engines of the USS TEXAS, a world war 1 veteran and now museum ship. USS Texas BB-35 had her keel laid April 1911 in Virginia USA with completion coming in March 1914. She is the last of the world’s “dreadnought” style, big gun battleships and was the most powerful weapon in the world boasting 5 twin turrets equipped with 14” guns which could reach out 14 miles. She is the only surviving US naval ship to have served in both world wars. Her last official duty was to make three “magic carpet” voyages from Pearl Harbor to California, bringing nearly 5000 troops home from the Pacific. After completion of her World War II repatriation duties, and de-commissioning in April 1948, she was scheduled to be used as a bombing target, but Texas citizens launched a successful campaign to have her saved. The U.S. Navy towed her to South East Texas to become the nation’s first permanent memorial battleship when she took up residence at the site of the famous San Jacinto battleground and memorial where she has rested since April 1948.  Originally equipped with 14 scotch type, coal fired boilers, a modernisation in 1925 saw these replaced with six 3-drum water tube boilers and modern oil firing equipment. Her twin funnels were removed in favor of just a single which had divisions inside for each boiler. Large turbine driven fans forced air into the pressurised stokeholds which are quite spacious after removal of the old boilers. The single funnel has me intrigued, because it is much lower than the control tower just forward, and I was scratching my head as to what they do when steaming with a strong tail wind? Do they speed up faster than the wind, or alter course to prevent the boiler flues killing the helmsman up in the tower? The whistle was recently re-mounted after many years, and was test blown on air. A solenoid valve controls it electrically from the bridge. The 4 cylinder triple expansion Engines 39″, 63″ & 83″ x 48″ stroke…. 14,000 IHP Big T’s 2 massive engines produced 14,000 IHP which pushed her 34,000 tons of displacement through the seas at 20.4 knots while the 1,645 crew went about their daily business. She was built in the period when reciprocating steam engines were being replaced with turbines, and only 1 more warship was built with real steam engines, commissioned one month after Texas, the “New York” class battleship USS New York. (The first steam turbine warship HMS Dreadnought was built in 1906 with Parsons turbines) The massive cylinder block makes the engine stroke look small, and I expected the engine to be much taller. But it was explained to me that there was limited deck space above the engineroom requiring some compactness. All bearings are supplied with forced lubrication at 50 psi and the crank spaces are enclosed with galvanized sheet steel to within 18” below the cylinders. Each propeller is manganese bronze, 18’ 7 ¼ ” diameter and 19’ 11 ½ “ pitch.

Originally equipped with 14 scotch type, coal fired boilers, a modernisation in 1925 saw these replaced with six 3-drum water tube boilers and modern oil firing equipment. Her twin funnels were removed in favor of just a single which had divisions inside for each boiler. Large turbine driven fans forced air into the pressurised stokeholds which are quite spacious after removal of the old boilers. The single funnel has me intrigued, because it is much lower than the control tower just forward, and I was scratching my head as to what they do when steaming with a strong tail wind? Do they speed up faster than the wind, or alter course to prevent the boiler flues killing the helmsman up in the tower? The whistle was recently re-mounted after many years, and was test blown on air. A solenoid valve controls it electrically from the bridge. The 4 cylinder triple expansion Engines 39″, 63″ & 83″ x 48″ stroke…. 14,000 IHP Big T’s 2 massive engines produced 14,000 IHP which pushed her 34,000 tons of displacement through the seas at 20.4 knots while the 1,645 crew went about their daily business. She was built in the period when reciprocating steam engines were being replaced with turbines, and only 1 more warship was built with real steam engines, commissioned one month after Texas, the “New York” class battleship USS New York. (The first steam turbine warship HMS Dreadnought was built in 1906 with Parsons turbines) The massive cylinder block makes the engine stroke look small, and I expected the engine to be much taller. But it was explained to me that there was limited deck space above the engineroom requiring some compactness. All bearings are supplied with forced lubrication at 50 psi and the crank spaces are enclosed with galvanized sheet steel to within 18” below the cylinders. Each propeller is manganese bronze, 18’ 7 ¼ ” diameter and 19’ 11 ½ “ pitch.  Steam is supplied from the 6 water tube boilers at 265 psi, and there are no flat slide valves on the engine, instead a single piston valve on the high pressure cylinder, and double piston valves on all others. The cooler exhaust steam having its own separate piston valve provides a small increase in efficiency. Exhaust from the intermediate cylinder is exhausted to the header pipes on one side of the engine which splits in both directions to feed the piston valves for the 2 LP cylinders, then leaves on the opposite side of the engine through combining piping to carry it to the main condenser.

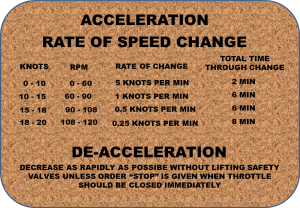

Steam is supplied from the 6 water tube boilers at 265 psi, and there are no flat slide valves on the engine, instead a single piston valve on the high pressure cylinder, and double piston valves on all others. The cooler exhaust steam having its own separate piston valve provides a small increase in efficiency. Exhaust from the intermediate cylinder is exhausted to the header pipes on one side of the engine which splits in both directions to feed the piston valves for the 2 LP cylinders, then leaves on the opposite side of the engine through combining piping to carry it to the main condenser.  The steering engine is larger than some of the ship’s engines I have worked with, and it’s only used to move the rudder! It can be controlled from the ship’s bridge, an emergency steering space below within the amour plating of the ship which is just a room with a wheel and voice pipe, and at the steering engine itself, there is a wheel which can be engaged if required. The main condenser vacuum is maintained by an interesting double cylinder air pump, while a various general service pumps are arranged around the spacious engine room. Do you remember the old Westinghouse air compressors found on steam locomotives? Well there are 4 mounted across the engineroom aft bulkhead which fill some handsome looking riveted are receivers with air. An interesting plaque is mounted at the engine control platform for rates of change for increasing the speed of the main engine. After long thought on this, I came to the conclusion that increasing steam pressures within the engine often causes some condensation of steam in the lower pressure parts of the engine.

The steering engine is larger than some of the ship’s engines I have worked with, and it’s only used to move the rudder! It can be controlled from the ship’s bridge, an emergency steering space below within the amour plating of the ship which is just a room with a wheel and voice pipe, and at the steering engine itself, there is a wheel which can be engaged if required. The main condenser vacuum is maintained by an interesting double cylinder air pump, while a various general service pumps are arranged around the spacious engine room. Do you remember the old Westinghouse air compressors found on steam locomotives? Well there are 4 mounted across the engineroom aft bulkhead which fill some handsome looking riveted are receivers with air. An interesting plaque is mounted at the engine control platform for rates of change for increasing the speed of the main engine. After long thought on this, I came to the conclusion that increasing steam pressures within the engine often causes some condensation of steam in the lower pressure parts of the engine. In June 2012, a massive water leak was discovered in the engineroom which put her future under a cloud. But there has since been money raised to ensure she is repaired and will be around for many

In June 2012, a massive water leak was discovered in the engineroom which put her future under a cloud. But there has since been money raised to ensure she is repaired and will be around for many  years to come.

years to come.