The Nigerian Project

You could say I am a person who gets bored easily. So it’s fortunate for me that my boss recognises this and is always finding interesting things for me to do! Here in Geelong, it was decided to upgrade the control instrumentation across the whole refinery, going to a DCS computer screen based system, and I was given the job of designing graphics, commissioning the control panel, then transfering each instrument “one at a time” from the old pneumatic system to the new DCS.

Nobody except me, fully understood how it all worked, so it was only natural that I should take on a training role and teach everyone how my masterpeice worked. But after 7 years of training, I again got bored so my boss sent me across the seas to start up and commission a new liquified natural gas (LNG) plant in sunny Nigeria! Whow!!! What a culture shock!

Nigeria -Africa’s sleeping giant

With a population of more than 120 million people (nobody is really sure) Nigeria is a busy and interesting country. I was fotunate enough to bring my family with me, Riley aged 4 years, and Mitchell was 7 years old. My wife Anita and myself had travelled extensively when we were younger and thought this place could not be more of a culture shock than when we arrived in Egypt all those years ago. But boy!!! We were wrong!

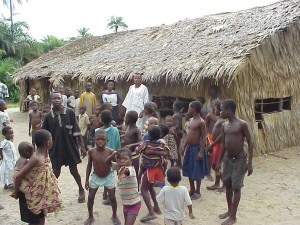

Please excuse the quality of some photos, as it’s very difficult to take photos in Nigeria as most people are superstitous and think you can have power over them if you have their photo. So most people are offended and upset if you pull a camera out in public. But the time we visited the lighthouse village they all wanted to get in the photo! Can you see Mitch in the middle of all the black faces?

Please excuse the quality of some photos, as it’s very difficult to take photos in Nigeria as most people are superstitous and think you can have power over them if you have their photo. So most people are offended and upset if you pull a camera out in public. But the time we visited the lighthouse village they all wanted to get in the photo! Can you see Mitch in the middle of all the black faces?

![]() Nigerian Liquified Natural Gas (NLNG)

Nigerian Liquified Natural Gas (NLNG)

Nigeria had been exporting crude oil for the past 40 years. It had been done on a shoe string budget while trying to pay off the crooked Nigerian Military government. As a consequence, the natural gas that came up with the oil was simply flared off in a short sighted greedy attempt to exploit the oil reserves with as little capital expenditure as possible. When the space shuttle orbitted the Earth, they always new when they were over Nigeria as the hundreds of burning flares could be seen from space. What a waste! It makes your carbon footprint pale into insignificance when you think about how dumb this all was. To this day, part of the company slogan was “extinguishing the flares of Nigeria”. And what an environmental mess it was too. If we left our white plastic table and chairs out in the garden overnight, they would have a grey tinge by morning, from the dark sooty covering brought down with the night dampness.

NLNG was formed around 1980 with a bold scheme to capture this gas, reticulate it to the coast, liquify, and export it for even greater returns from the oil industry for Nigeria. But finding shareholders to invest with the unstable Nigerian government in those crazy days of Military rule was almost impossible. Even pleas to the World Bank on environmental grounds fell on deaf ears. Nearly 20 years past until a stable government was on the horizon before FID (final investment decision) was achieved. The company had even built tanker ships which had been laid up around the world waiting for this day. It was funny to see the first tankers which were basically brand new arrive with technology that was 25 years old!

Phase One of our project was to build 2 LNG trains, the design for which was also 20 years old. They were built from the original drawings, started up, then shutdown and modified. It always sound crazy to do this, but believe me, going back into the design phase, and then go back to the shareholders all over again would take longer and be more expensive, so you just build it as designed and then modify later. For example, the huge gas compressors were built with seals that required a complex wet system with seal oil tanks and pumps and degassifiers. This was later replaced by the simple carbon dry gas seals that had been invented since the original design was put on paper.

Want to know more about dry gas seals? Click here to read the presentation I made for my operator apprentices. Compressor dry gas seal system

When I left my job in Geelong Australia, I was known as “the guru of steam” after being the operations trainer for seven years in which time I had taught and examined many people for their government license to operate steam machinery. When I arrived in Nigeria, the first thing I asked was, “where are the boilers and steam engines?” They looked at me strangely, breaking to me gently, there were none. But we have some lovely gas turbines… almost the same thing. Imagine my surprise when the first LNG ship arrived and I rushed down the engine room (as I did many times in Geelong) only to find the ship was steam powered! I told them I had a marine steam engineers certificate, and they immediately offered me a job as steam engineers were hard to come by. But working up to 6 months at sea without touching land didn’t have much appeal.

Transporting LNG by steam ship makes perfect sense. It is stored in the cargo tanks at pressures just above atmosphere and boils off for the entire journey with the gas given off directed into the boilers to burn as fuel. Imagine carrying a kettle of boiling water to your neighbour’s house. You need to run quickly so it doesn’t get cold, and in our case it’s still plugged in because at -162 degrees, the warmth from the outside is enough to make it boil even with good insulation in between. So LNG ships are propelled by the swift steam turbines and typically achieve up to 22 knots. Pretty fast for a ship around 85,000 tons! Gotta get there quickly before it all boils away! And they even leave a little in the tanks when discharging to get them back, and to keep the tanks cold ready for instant filling.

Transporting LNG by steam ship makes perfect sense. It is stored in the cargo tanks at pressures just above atmosphere and boils off for the entire journey with the gas given off directed into the boilers to burn as fuel. Imagine carrying a kettle of boiling water to your neighbour’s house. You need to run quickly so it doesn’t get cold, and in our case it’s still plugged in because at -162 degrees, the warmth from the outside is enough to make it boil even with good insulation in between. So LNG ships are propelled by the swift steam turbines and typically achieve up to 22 knots. Pretty fast for a ship around 85,000 tons! Gotta get there quickly before it all boils away! And they even leave a little in the tanks when discharging to get them back, and to keep the tanks cold ready for instant filling.

My interest in ships was spotted early and I spent considerable time commissioning and starting up the jetty. I later ran the jetty as a shift supervisor, and even a short period as storage and loading master, the best job I ever had before getting transfered to the next project building the second jetty for LPG export. I loved being on board all the ships, but the LNG Delta was my favourite. Originally built as the “El Paso Southern” her engineroom had been designed by the US navy design team and was a real greyhound with more than 40,000 hp steam turbine engines. I got to know the crew here best and often spent long hours down the engine room. When I got back to the office my boss often asked me “Where have you been? We were calling you on the radio for ages!” Oh, sorry… I was helping the Third Engineer do a condenser clean. Or, they were doing an acid clean on the evaporators and I was just watching. The old Scottish chief engineer Willy took the old tatty engineroom, and with hard work of cleaning and painting had her looking spic, span and Bristol fashion in the 2 years I knew her. And the engine control room was still the old mimic panel style from the 1970’s. Beautiful! (See photo middle above)

Here is my list of NLNG Tankers I worked with from those days.

Life in camp

No expense was spared when they built the residential complex for the company. Because of it’s remote location, the company recognised getting people there would be difficult, so the RA was made “family friendly” with shopping centres, sports facilities, restaurants, schools for the children and a huge olympic sized swimming pool. When the Nigerian government saw this they enquired about using it to train their olympic athletes until our manager told them the pool was only 49.9 metres in length making it unsuitable. They believed him…

Of course being on the commissioning team we arrived before any of this was ready or open, so we lived closely with the construction camp. I remember a trip to the supermarket there- Anita asked me why they had one aisle for food, and four aisles stacked with beer. “It’s a batchelor camp” I explained. The poor wives were fairly bored in those early days with the biggest excitement starting with the rumours that a new container was arriving soon at the supermarket. Finally when it did land (always later than expected) the ladies of our camp would be like crazy women fighting over chocolate biscuits, ice creams and other unusual items. All very funny now! Who was to know that three years later, the families would all be sent home because the security situation was becoming untenable as a campaign was waged against the oil industry demanding more of the oil wealth to be spent locally, and who could blame them after being the world’s fifth largest oil producing nation with very little to show for 40 years of production?

This page is still under construction